Company

Catalano, synonymous with innovation, quality and design, is a leader in the ceramic bathroom furnishings sector. Founded in 1967 in Fabrica di Roma, it is an Italian company with a solid industrial culture, which has been able to combine technology and automation with the craftsmanship cultivated in the area for generations.

- Area

130.000Mq (of which 80.000 covered)

- Production

-

- 500.000pieces produced annually

-

- 65%Export

35%Domestic

- 65%Export

-

- Employees

250

The Region

A countryside of exquisite beauty that stretches harmoniously along the course of the river Tiber. An abundant, fertile land steeped in history and traditions that go back millennia. This was where the ancient Faliscan civilisation arose, famed for its refined ceramics. Keeping ancient techniques alive and handing down skills from generation to generation, this area north of Rome has developed into one of the world’s most advanced centres of ceramics production.

100% Made in Italy

All Catalano products are 100% made in Italy because they are all conceived, designed, and manufactured at our single global production site near Rome. The “Made in Italy” logo is hot-stamped in an unalterable way to guarantee the origin of our products.

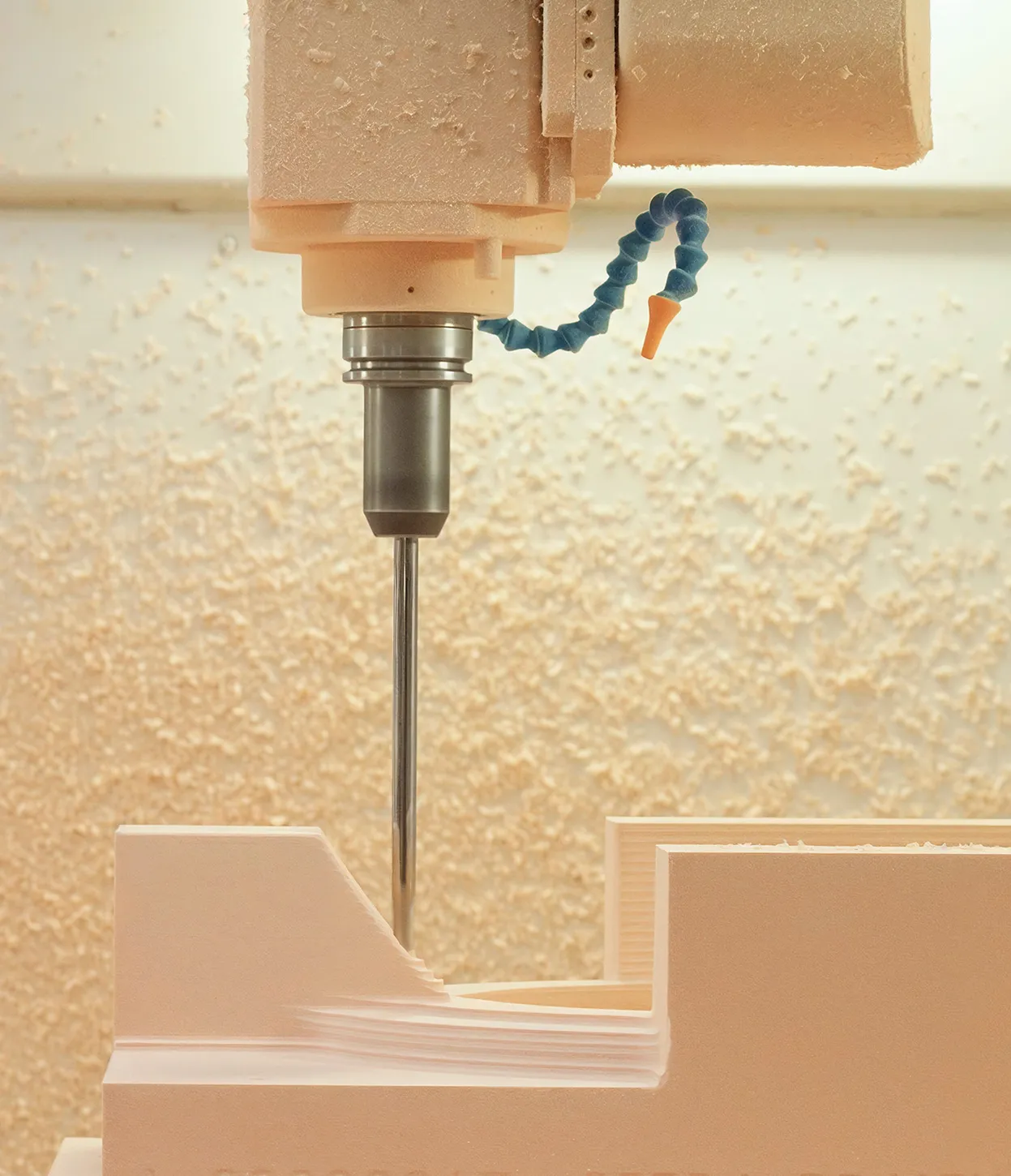

Design and Prototyping

Design, development and prototyping of our products are all performed in-house. Every tiny detail is carefully scrutinized because we want our products not just to be beautiful but functional, ergonomical and durable.

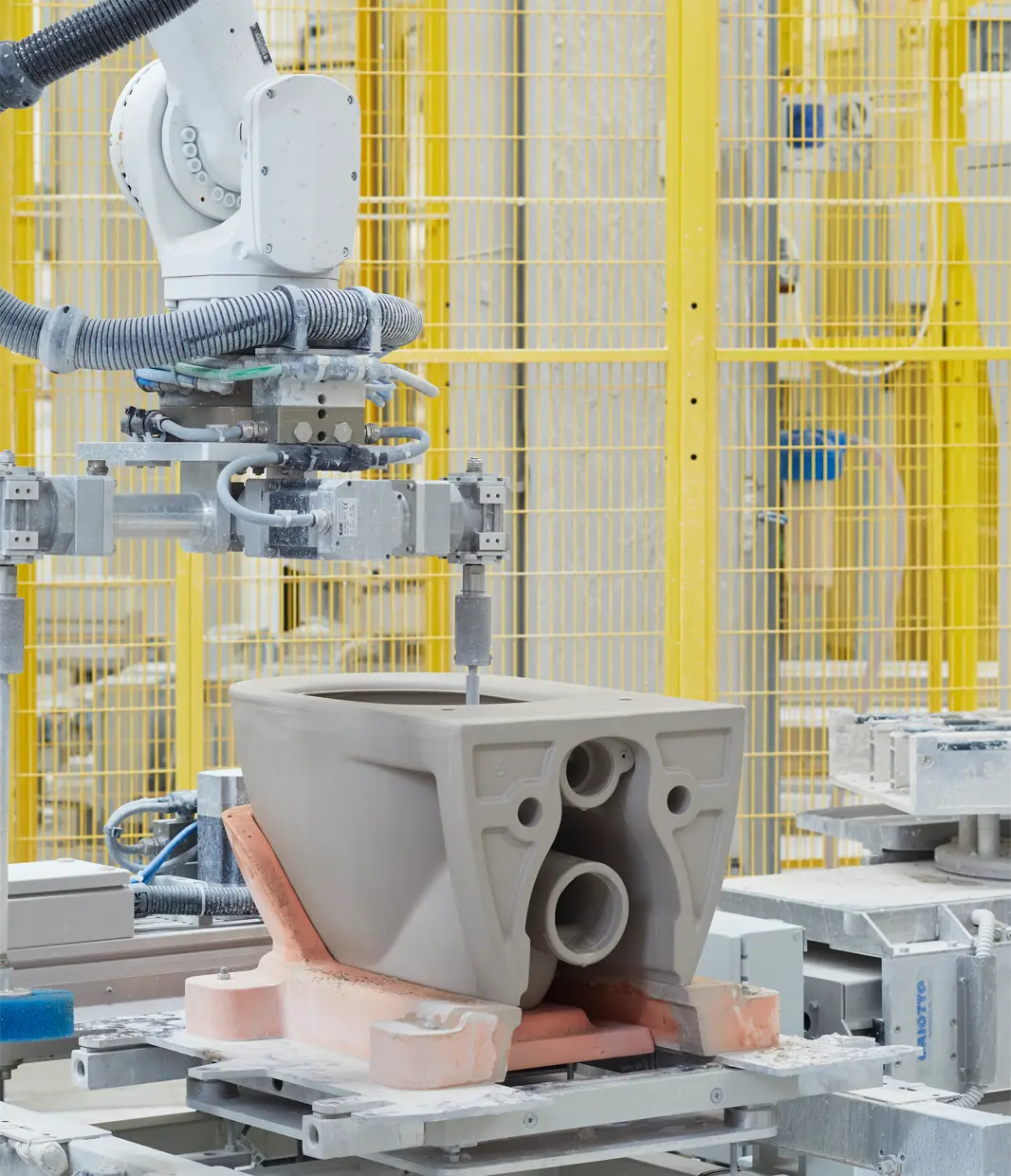

Manufacturing

The facilities at our plant in Fabrica di Roma can boast of the world’s most cutting edge equipment in the sector of ceramics manufacturing. We use advanced automation and technologies to ensure that the very highest quality standards are always met. We implement certified and sustainable processes that are highly energy efficient and that significantly reduce environmental impact. Behind all this is our awareness that the experience, passion and professionalism of everybody who works in the company is what really creates the added value our products are known for: conceived, designed and produced with attention to detail and entirely in Italy.

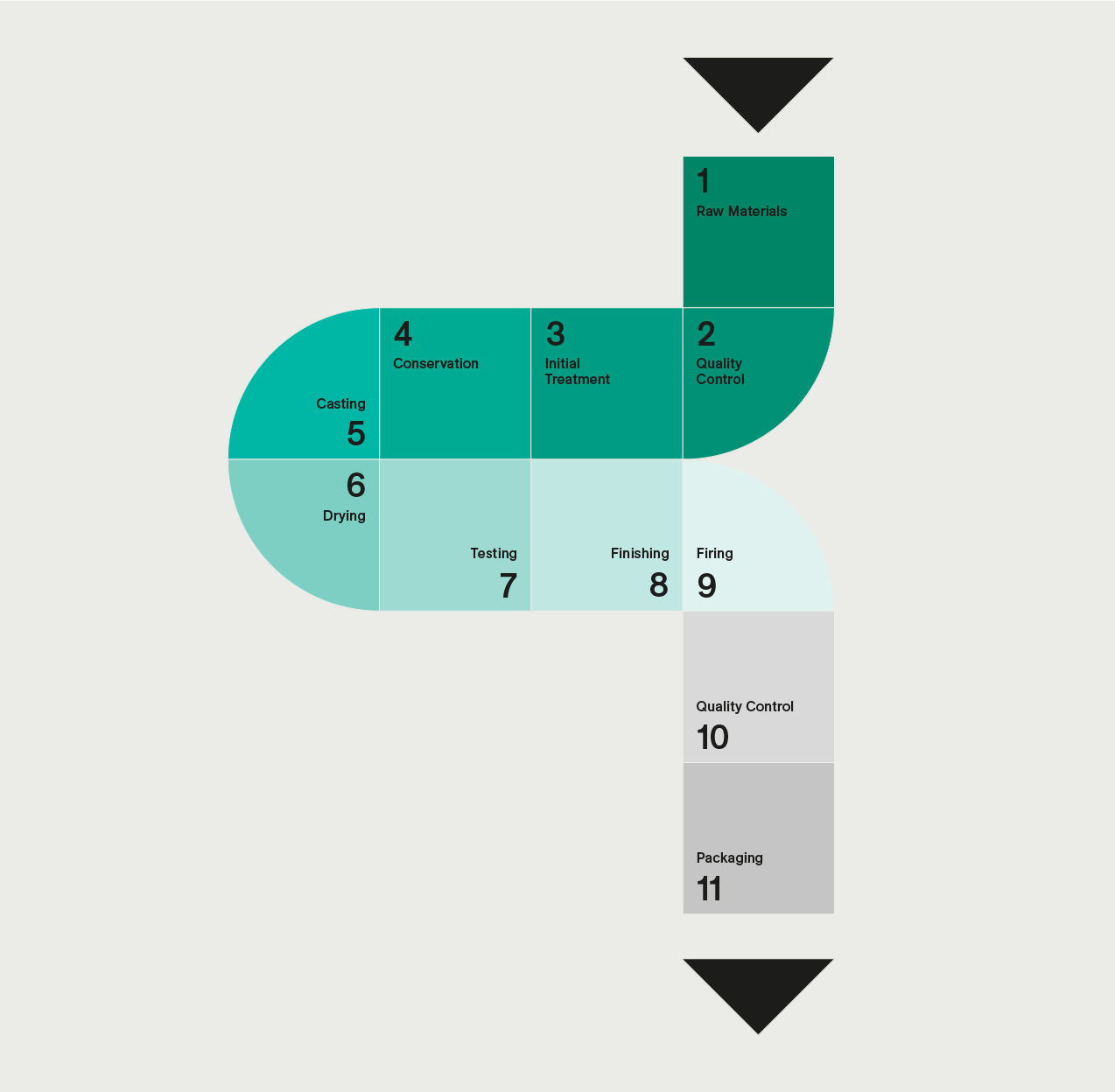

- Raw Materials

The raw materials brought to the plant entrance are collected on site and, if necessary, dried. They are then stored in special silos. Small amounts of components are also supplied directly in bags (big bags). Some raw materials require mechanical treatment, preliminary grinding. This process is followed by the preparation of the slip, by mixing the raw materials with water and passing the mixture through a special sieve. A custom blend of raw materials (oxides, special sands, frits, etc.), prepared for the purpose in-house, is agitated with the addition of water before being sieved and then milled. Binder is added shortly before processing.

- Mold Construction for Casting

Molds used in casting—crucial for the production of ceramic sanitary ware—are manufactured according to their intended application. For high-volume production, molds made from a special porous resin are used, specifically designed for high-pressure casting systems. For low-volume items, or products with particular structural features, plaster molds are used instead, suitable for traditional low-pressure casting systems.

- Drying

After casting ceramic products are submitted to various drying processes depending on their complexity.

- Glazing and Firing

In this phase, glaze is applied to the dried unrefined product, either by hand or fully automatically using robots. Any excess glaze (overspray) is recovered and reused.

Next, the glazed sanitary ware is fired in tunnel kilns at a temperature of 1250 °C for approximately 22 hours. The glazes are prepared in-house using specially selected raw materials. The mixture is first milled and sieved, then combined with a special binder, and finally diluted with water.- Selection

After firing, each product is carefully inspected by our skilled craftsmen, who assess every single item. Only products that meet the quality standards are selected for packaging.

- Packaging, Storage, and Shipping

Products that do not meet quality standards can often be retouched and reprocessed in an intermittent kiln, or sent for material recycling as waste. To ensure consistently high quality, thorough inspections are carried out—from the delivery of raw materials through every stage of the production process. The products are then packaged according to product type and placed in cardboard boxes. Next they are stacked on wooden pallets and wrapped with shrink film, stored and shipped.

Raw materials

Water, earth and fire are the elements that, when expertly combined, give rise to ceramic products. We ourselves carefully select and work the clays and materials needed for production to ensure that our products always meet the highest quality standards and last over time.

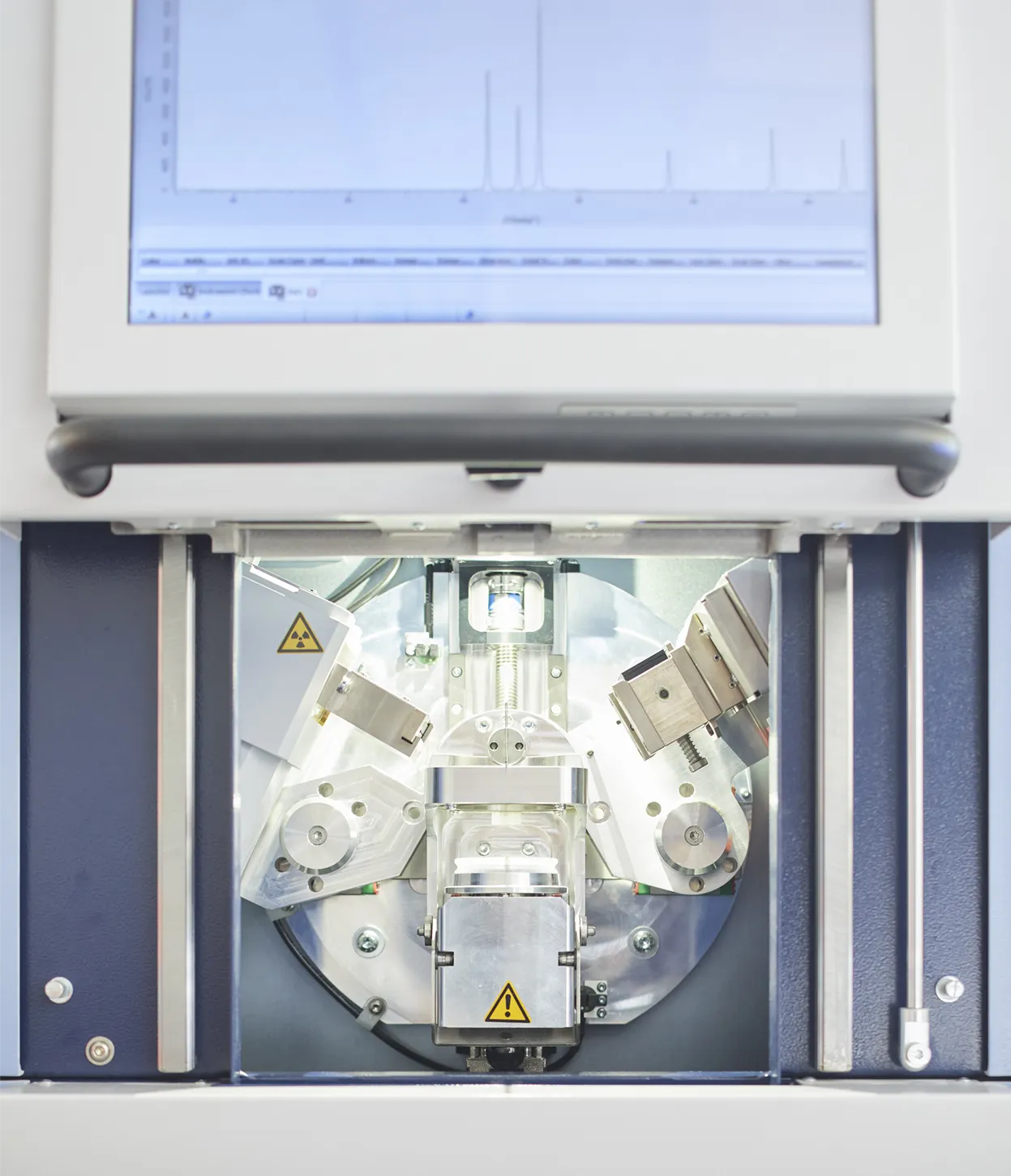

R&D Laboratory

A highly specialized environment where the physical and chemical properties of our raw materials are analysed to guarantee their quality and compliance with specific standards; here new materials and processes are researched and tested with the aim of further improving the properties of our ceramic products and meeting both market needs and environmental regulations.

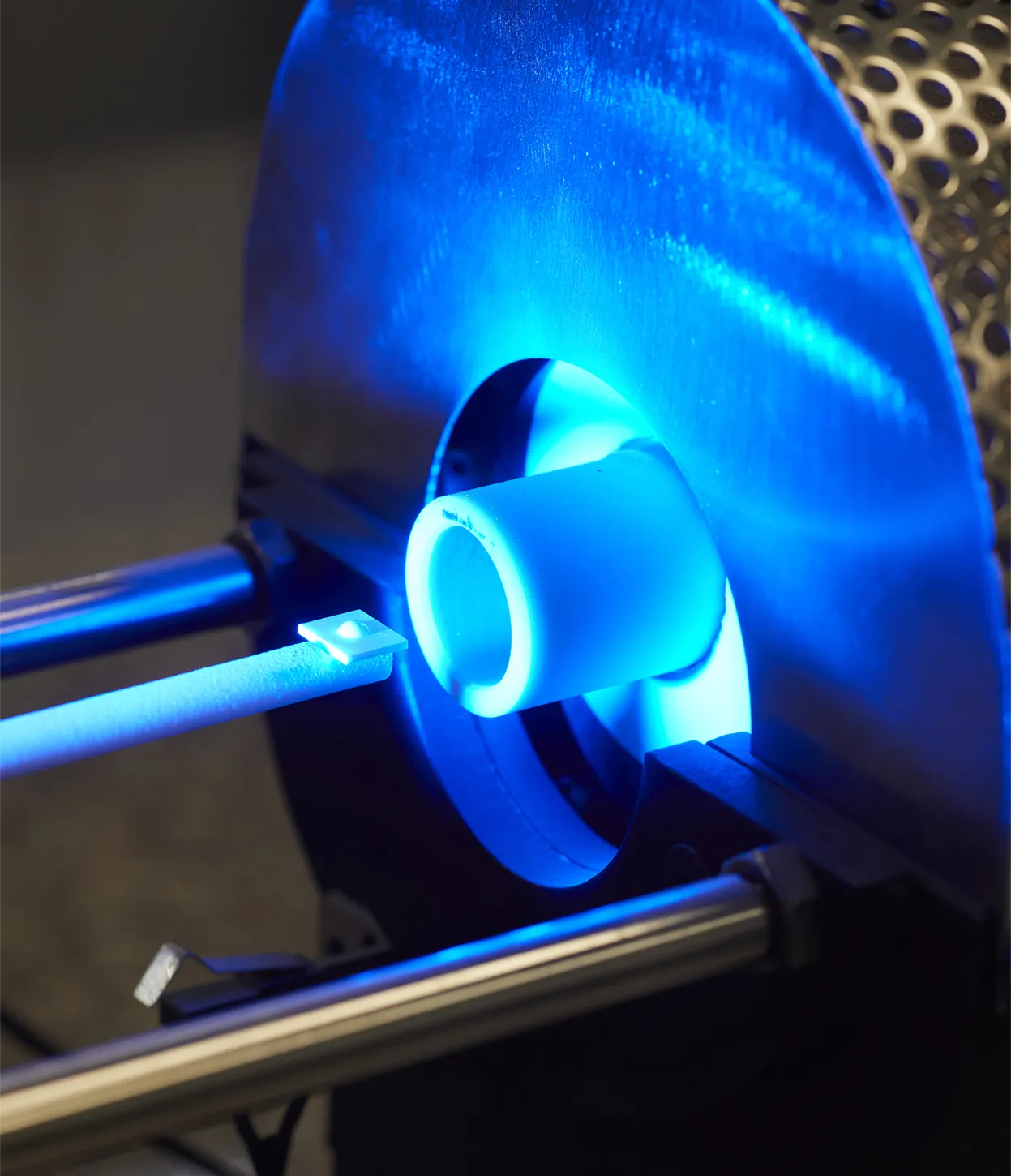

Cutting Edge Technology

The company evolution is the result of an innate attention to technological innovations able to face the demand of increasingly challenging and globalized markets. Resource management, design, modelling and production phases are organized using highly digitalized and automated systems.

Catalano uses smart manufacturing procedures for maximum optimization of production processes. The increasing investment in robotics has led to a very high level of automation and precision, leaving to the expertise of our skilled craftsmen the final touch of product improvement.

Investing in the Future

At Catalano we firmly believe in the importance of investing time and resources in the education of young people, actively collaborating with high schools in the ceramic district. This initiative represents a significant step towards social sustainability and our commitment to the community in which we operate.

Sustainability

Our manufacturing processes, besides enhancing the quality of human labour, also embrace sustainable practices such as using energy generated from our onsite solar power

plant, or treating and recycling process water and waste materials. We use highly energy efficient equipment and energy-optimized ovens to reduce environmental impact.

We are constantly striving to explore and develop new solutions that will raise the overall sustainability of our production. We also support international projects aimed at social, environmental and climate protection through the acquisition of carbon credits.

Certifications and Awards

Catalano was the first sanitary ware company in the world to obtain ESG certification (Environment, Social and Corporate Governance) and the first in Italy to achieve an EPD (Environmental Product Declaration). In addition to having an ISO 9001:2015 certified quality management system, Catalano is also certified for aspects of environmental management under the standard ISO 14001:2015, for its energy management systems ISO 50001:2018 and for greenhouse gas emissions ISO 14064:2019.

- Company certifications

-

Download

DownloadCertification for the impact on the environment and territory, on the social impact and internal aspects of the Company e to its administration.

Download

DownloadProduct certification focusing on the environmental performance of the Life Cycle Assessment (LCA).

Download

DownloadThe UNI EN ISO 9001:2015 standard defines the criteria for a quality management system focused on process efficiency and adopts a risk-based approach. Certification first obtained in 2012 and renewed in 2021.

Download

DownloadUNI EN ISO 14001:2015 provides an in-depth framework for managing business operations with the goal of reducing environmental impact, in compliance with all legal requirements, and strengthening relationships with all stakeholders.

Certification was first obtained in 2015 and renewed in 2021. Download

DownloadThe UNI CEI EN ISO 50001:2018 standard on Energy Management Systems enables the implementation and maintenance of a system aimed at continual improvement of energy performance. Certification was first obtained in 2022.

Download

DownloadUNI ISO 45001:2018 defines the requirements for an occupational health and safety management system, with the goal of continuously improving risk prevention and worker protection. Catalano obtained this certification in 2024, confirming its ongoing commitment to ensuring safe working environments in compliance with international standards.

The ISO 14064:2019 standards are aimed at providing credibility and assurance to the processes of greenhouse gas (GHG) reporting and monitoring, both in terms of organizational emissions declarations and emission reduction projects.

Certification was first obtained in 2022. - Product certifications

-

- Awards

-

2003 Sistema Girly

2003 Sistema Verso

2008 Programma proiezioni

2014 Impronta 125

2015 Green

2017 Green Lux

2018 New Zero

2019 Ceramic Top

2021 Verso

2021 Newflush®

2004 Sistema Verso

2006 Sistema Verso

2015 Green

2016 Newflush

2018 New Zero

2003 Sistema ZeroDomino

2004 Sistema Verso

2005 Programma C

2005 Sistema VersoComfort

2006 Programma Roma

2009 Programma Muse

2009 Programma Proiezioni

2016 Newflush

2016 New Zero

2017 Green Lux

2018 Newflush®

2020 New Zero

2021 Edition

2019 Ceramic Top

2021 Edition

2013 Sistema Impronta

2004 Sistema Verso

2004 Sistema ZeroDomino

2006 Programma C

2006 Sistema VersoComfort

2009 Programma Muse

2009 Programma Proiezioni

2010 Programma Proiezioni

2011 Programma Muse

2018 Newflush®

1991 Sistema Sfera

2004 Orinatoio Girly

2000 Sistema Zero

2003 Sistema Zero+

2003 Orinatoio Girly

2016 Newflush®

1999 Sistema Luce

2001 Sistema Zero

2003 Sistema ZeroDomino

2003 Sistema Verso

2005 Programma C

2005 Sistema VersoComfort

2009 Programma Roma

2008 Programma Muse

2009 Programma Proiezioni

2008 Programma Muse

2003 Sistema ZeroDomino