Sustainability

Sustainable production has always been a priority for Catalano. We have made this commitment part of our governance structure, which has enabled us to pursue a continuous path of growth and improvement. The credibility of our actions is backed by the environmental certifications we have obtained for both our organization and our products. These achievements are the result of ongoing investments and our meticulous control over the entire production process, which we manage entirely within a single facility. This allows us to measure, monitor, and manage the data we collect with the goal of significantly reducing energy consumption and continuously improving the production process.

- Highlights

200 tCO2eavoided through the purchase

of carbon credits- 536 tCO2eavoided through

self-produced photovoltaic energy

- 100% of ceramic sludge reused by third parties

- 99,8% of waste sent for recovery

- 536 tCO2eavoided through

Human Capital

Every day, a team of highly trained specialists monitors and assesses the company’s environmental impact to ensure compliance with laws, permits, and environmental standards. However, the goals set by the company involve all personnel, who are actively engaged through ongoing awareness and training initiatives. We devote particular care and attention to our human capital, striving to provide each employee with a healthy, safe, and comfortable workplace where their needs and expectations are heard and met.

ESG (Environment, Social and corporate Governance)

Catalano was the first Italian company in the sanitary ceramics sector to obtain ESG certification. In line with the United Nations’ 2030 Agenda for Sustainable Development Goals (SDGs), our corporate sustainability system received certification with an ESG Rating of AA+ at 73.34%. This places Catalano among the companies with a well-established sustainability path, having already achieved 15 SDG targets.

Download- Goals

-

Certified Quality and Environmental Management

Besides having a quality management system certified to ISO 9001:2015, Catalano is also certified for environmental management under ISO 14001:2015, for energy management systems under ISO 50001:2018, for greenhouse gas emissions under ISO 14064:2019, and for occupational health and safety under ISO 45001:2018.

- Certifications

-

Download

DownloadThe UNI EN ISO 9001:2015 standard defines the criteria for a quality management system focused on process efficiency and adopts a risk-based approach. Certification first obtained in 2012 and renewed in 2021.

Download

DownloadUNI EN ISO 14001:2015 provides an in-depth framework for managing business operations with the goal of reducing environmental impact, in compliance with all legal requirements, and strengthening relationships with all stakeholders.

Certification was first obtained in 2015 and renewed in 2021. Download

DownloadThe UNI CEI EN ISO 50001:2018 standard on Energy Management Systems enables the implementation and maintenance of a system aimed at continual improvement of energy performance. Certification was first obtained in 2022.

The ISO 14064:2019 standards are aimed at providing credibility and assurance to the processes of greenhouse gas (GHG) reporting and monitoring, both in terms of organizational emissions declarations and emission reduction projects.

Certification was first obtained in 2022. Download

DownloadUNI ISO 45001:2018 defines the requirements for an occupational health and safety management system, with the goal of continuously improving risk prevention and worker protection. Catalano obtained this certification in 2024, confirming its ongoing commitment to ensuring safe working environments in compliance with international standards.

Heat Recovery

We set ourselves the goal of reducing the quantity of gas consumed in the firing and drying of our products by adopting an innovative heat recovery system. This led to improved environmental performance and a significant reduction in energy consumption.

Water Treatment Plant

Catalano’s purification plant is highly efficient and, in addition to reducing water consumption, allows 100% of our ceramic sludge to be reused by other companies in the ceramic sector for tile production.

Renewable energy

Ceramic production requires a great deal of energy at every stage of production. Our photovoltaic system, with a total capacity of 1,932.67 kW, allows us to cover 20% of our energy needs.

Total recycling of ceramic waste

All production waste, derived from natural raw materials, is 100% recycled as part of our manufacturing process. Every stage generates waste and residues which, in line with a circular economy, are reconverted. Even damaged or unsuitable products are crushed to obtain new raw material, which is then reintroduced into the production of other sanitary ware.

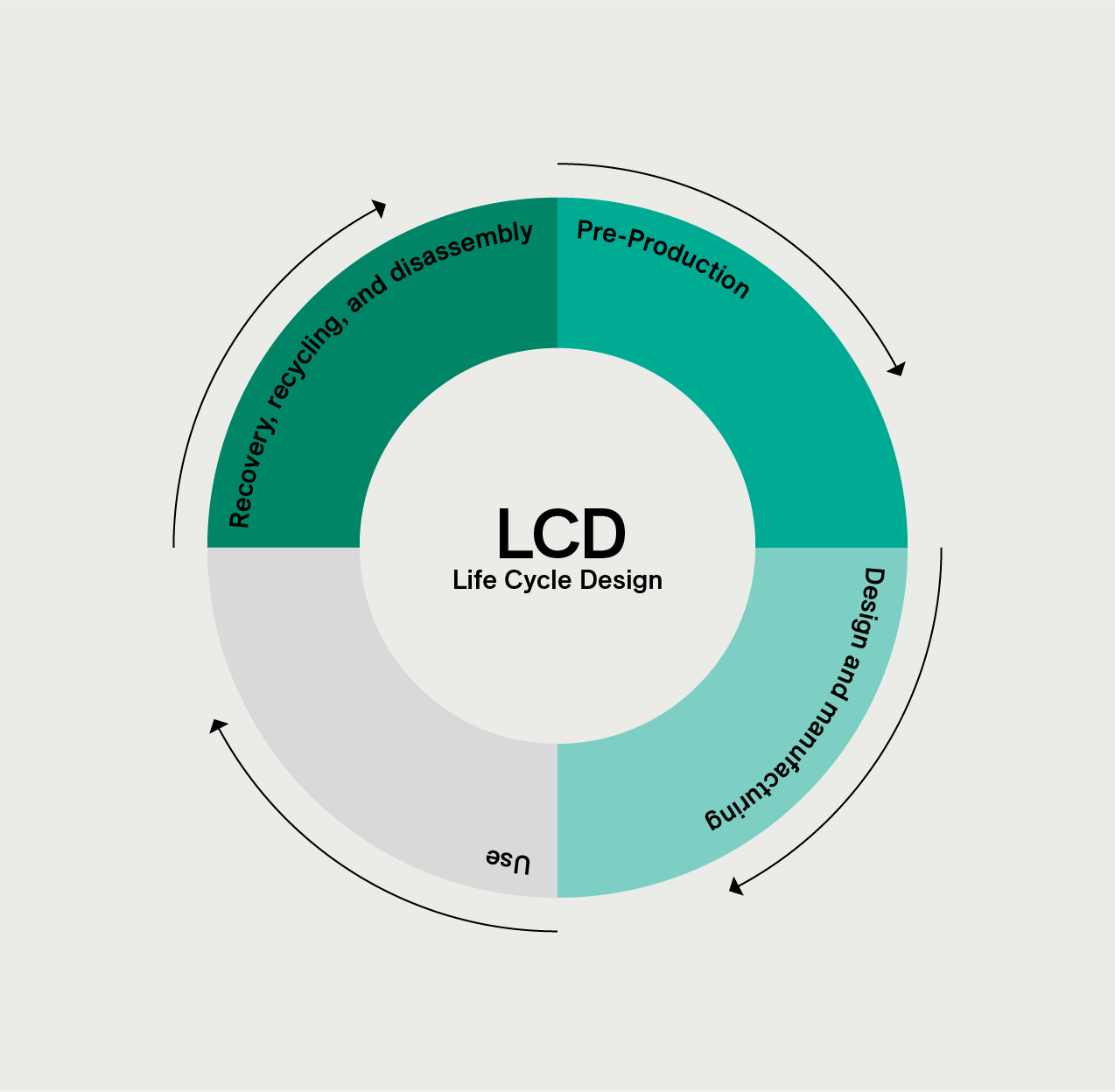

Circularity: The LCD Philosophy

Our production cycle is based on the LCD (Life Cycle Design) philosophy, which is part of the circular economy. This approach improves product quality, significantly reduces energy consumption and waste, and also optimises working conditions. The use of single-material ceramics, fired at over 1200°C, facilitates ‘design for disassembly’, i.e. design geared towards dismantling and recycling at the end of the product’s life cycle, planning every stage, from pre-production to recycling, to reduce environmental impact. In support of this vision, the LCA (Life Cycle Assessment) study quantifies the environmental impacts throughout the entire life cycle of the product. The results are formalised in the EPD (Environmental Product Declaration), which makes the ecological footprint transparent and comparable.

- Certification

-

Download

DownloadIn 2019, Catalano was the first Italian company in the sanitary ceramics sector to obtain EPD (Environmental Product Declaration) certification.

In 2024, Catalano updated its environmental declaration with two specific EPDs for the production of vitreous china and fire clay.

With these certifications, Catalano guarantees environmental control over the life cycle of its products (LCA), in accordance with rigorous international standards, placing itself at the forefront of all its competitors.